loading...

Shipping and VAT included

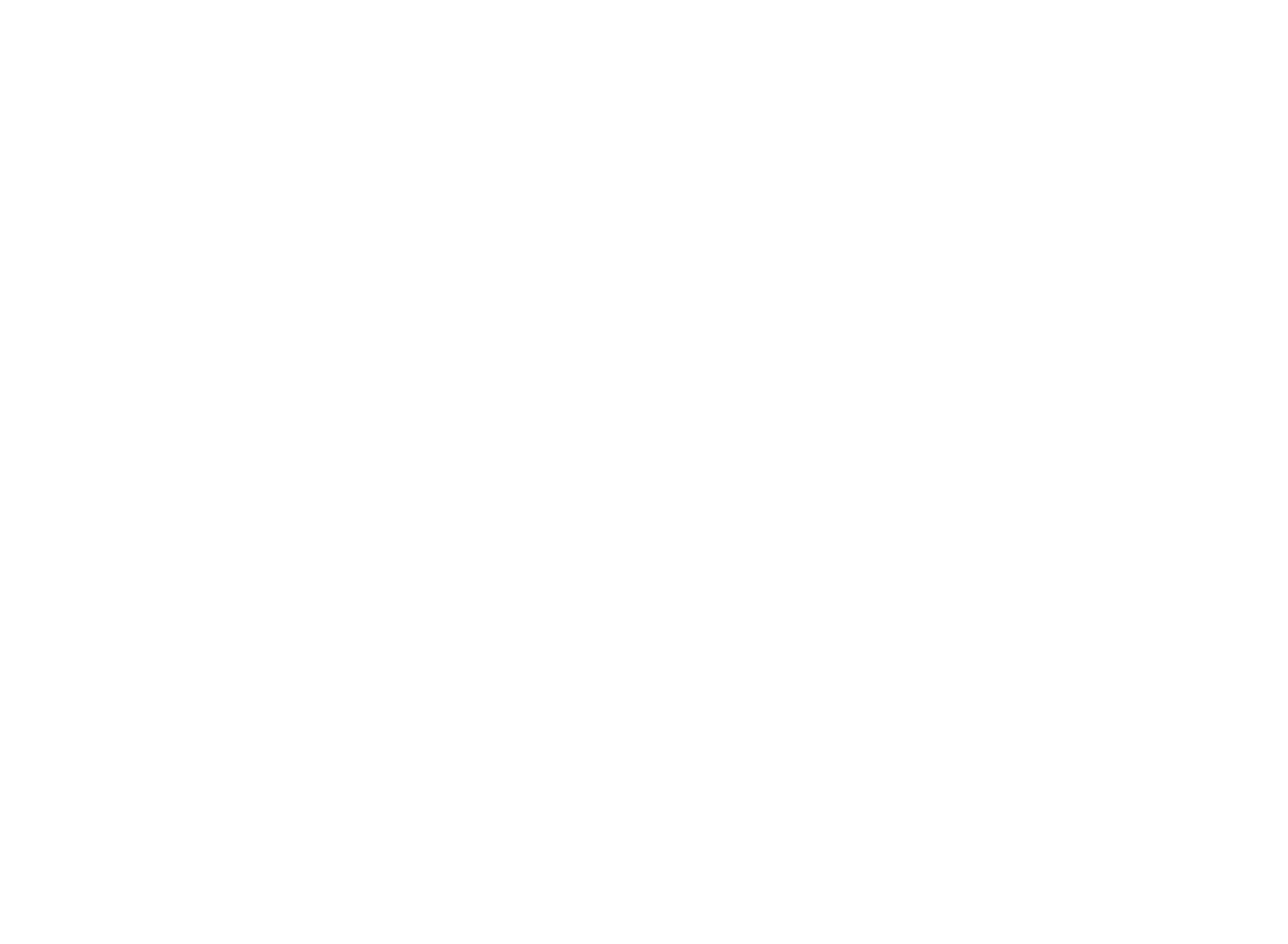

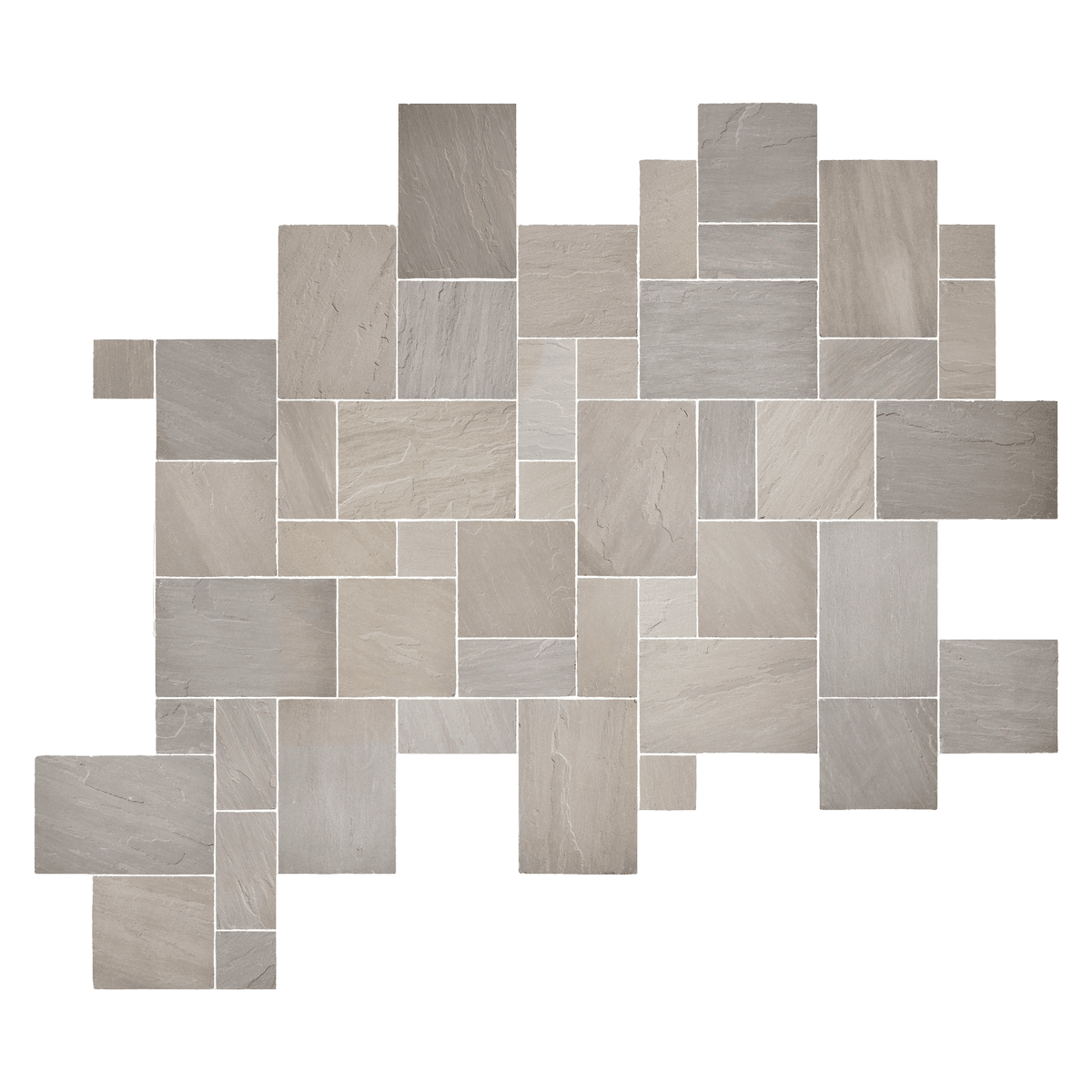

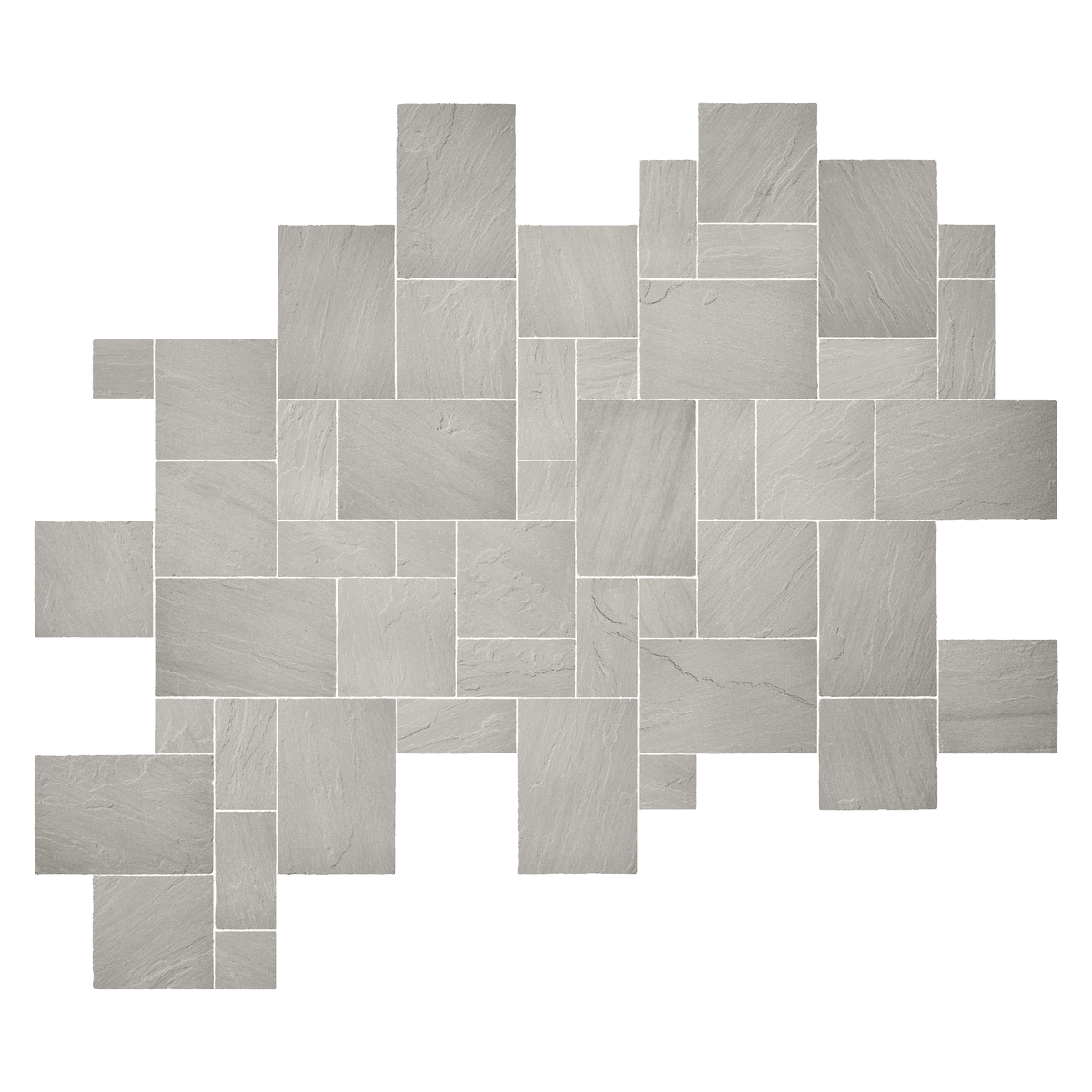

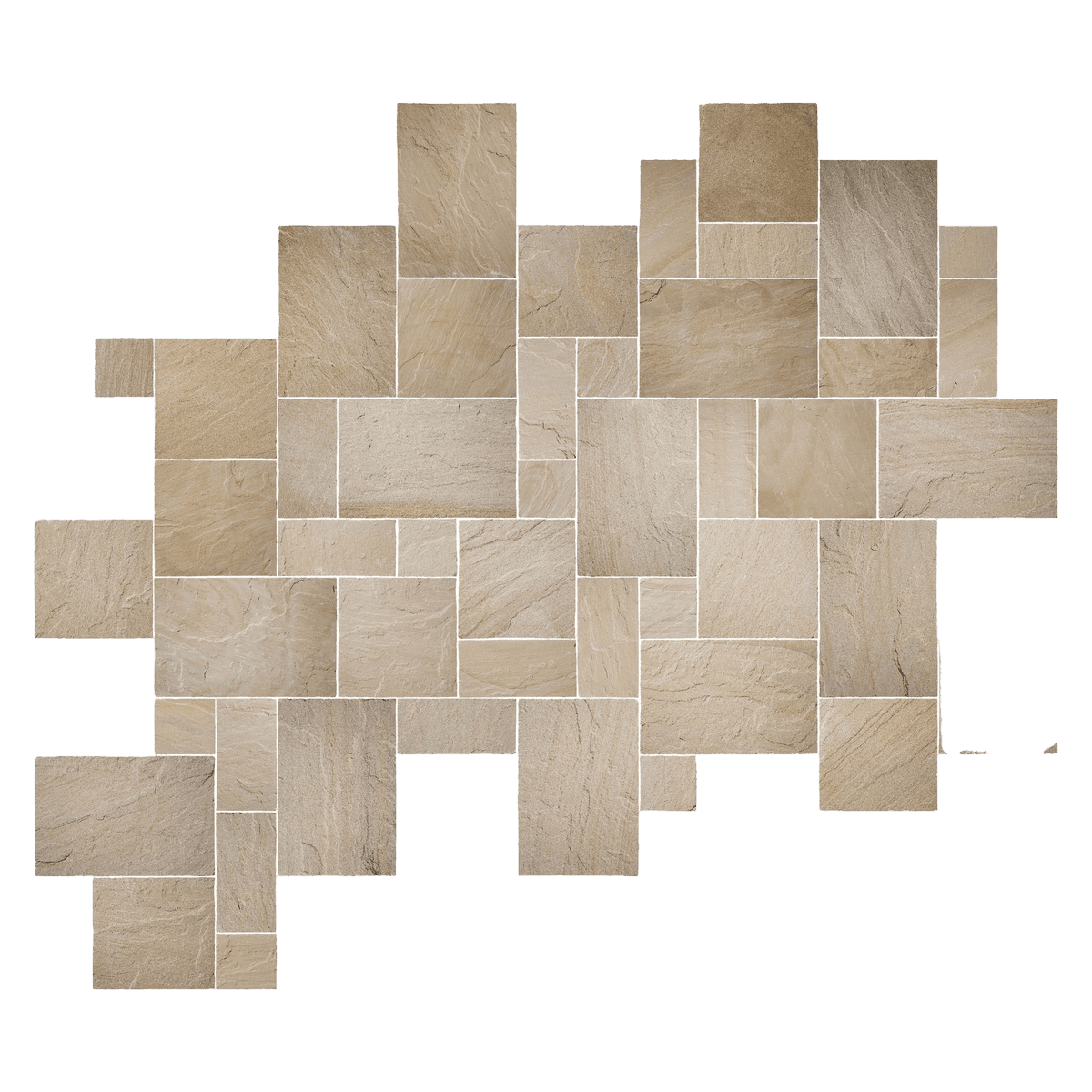

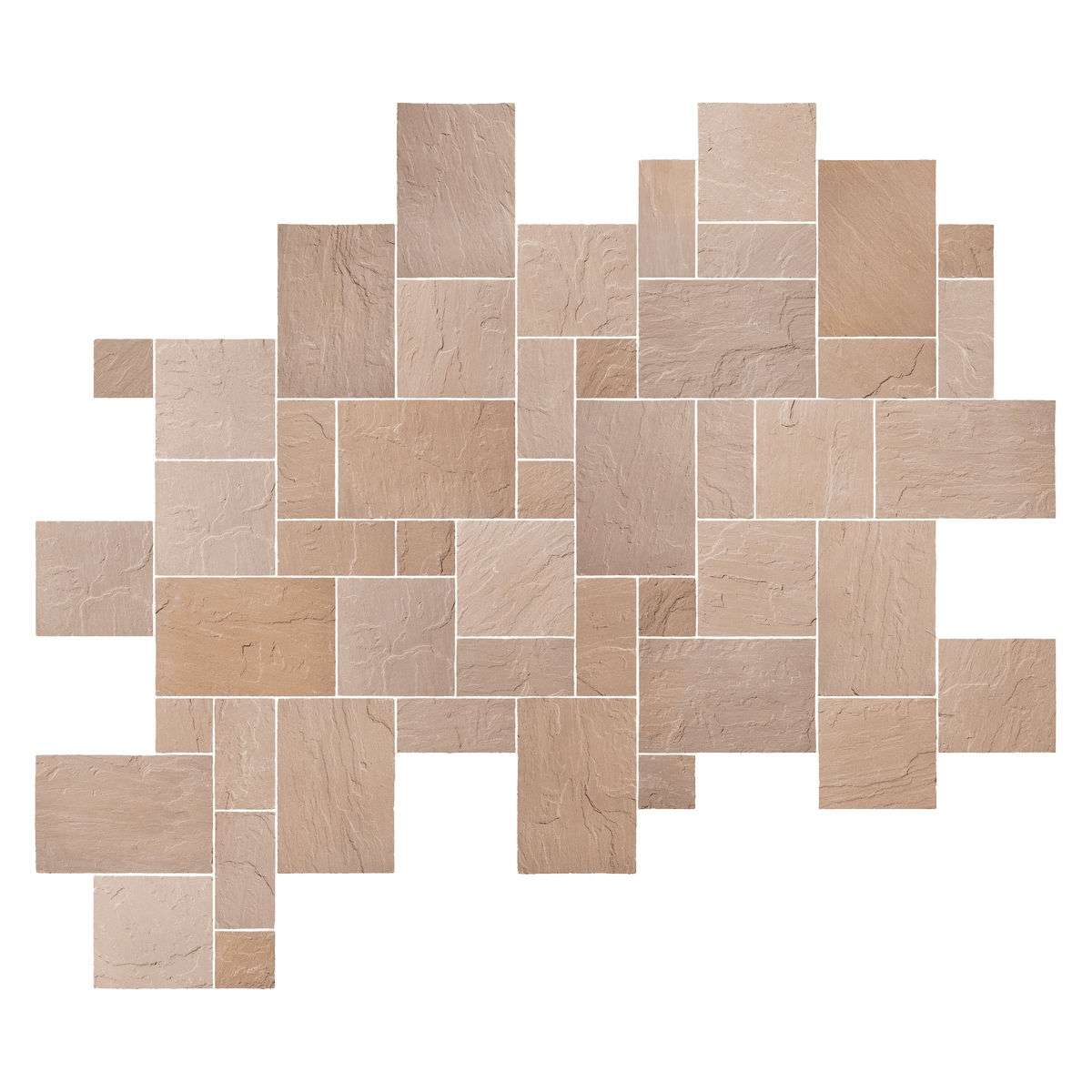

Our sandstone paving is a premium natural stone, meticulously hand-selected and hand-cut to a 22mm thickness. It’s our most popular range, prized for its wide variety of colours and sizes. Featuring a gently riven texture and distinctive natural variations in tone and veining, each piece’s unique character creates a stunning, harmonious blend across your paved area.

Delivered within 3–5 business days. Free shipping on all orders.